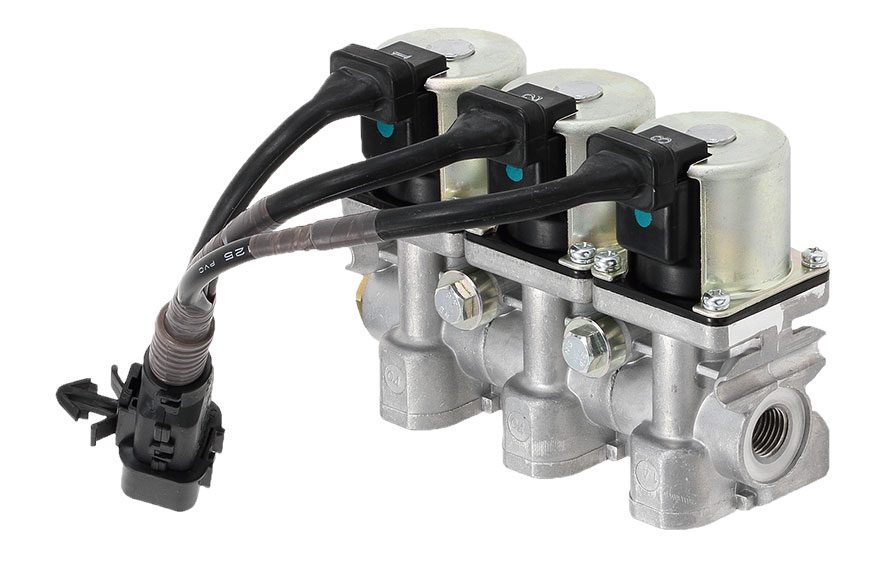

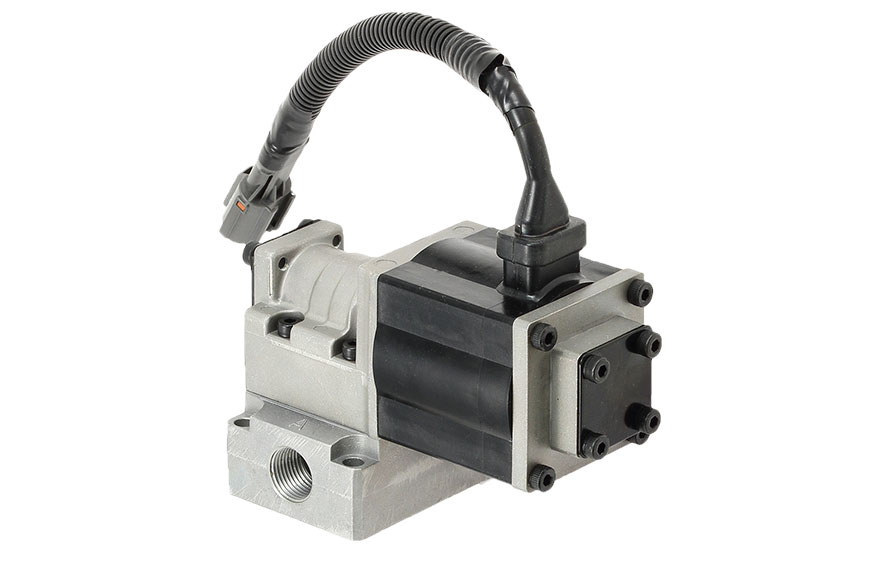

Positive Air Magnetic Valves

This valve is mainly installed in large and medium-sized trucks and buses for controlling various devices (PTO, transmission, exhaust brakes).

Moreover, its structure is designed to prevent the entry of water and dust in order to function properly even in the toughest environments.